The wood used to build tables and the hardware used to attach table legs would be considered direct materials. Small, inexpensive items like glue, nails, and masking tape are typically not included in direct materials because the cost of tracing these items to the product outweighs the benefit of having accurate cost data. These minor types of materials, often called supplies or indirect materials, are included in manufacturing overhead, which we define later. The first major category of nonmanufacturing costs encompasses all expenses related to soliciting customer orders and delivering the finished product. These selling and marketing costs begin the moment a manufactured item leaves the production floor and is ready for market distribution. Non-manufacturing costs – not incurred in transforming materials to finished goods.

Examples

Office supplies and the depreciation on non-production assets, such as the furniture and IT equipment in the corporate headquarters, are classified as G&A. Rent and utilities for the corporate office building are G&A costs, provided the facility is physically separate from the manufacturing plant. There may be options available to producers if the cost of production exceeds a product’s sale price.

Presentation of Manufacturing and Nonmanufacturing Costs in Financial Statements

These costs have two components— selling costs and general and administrative costs —which are described next. Costs that are not related to the production of goods are called nonmanufacturing costs23; they are also referred to as period costs24. Costs that are not related to the production of goods are called nonmanufacturing costs; they are also referred to as period costs.

Where does the time go?

By calculating manufacturing costs, manufacturers can better understand the elements that are driving up costs while identifying the most economical way to manufacture a product. Fluctuation of costs is yet another challenge that makes it harder to calculate manufacturing costs accurately, according to Fabrizi. The next step is to calculate the costs of utilities (electricity, water, or gas) that are directly used in the manufacturing process Travel Agency Accounting (for example, fuel used to operate the production equipment). While this is a simplified view of direct labor calculation, accountants also include the benefits, overtime pay, training costs, and payroll taxes when calculating the hourly rate. Now, add the value of existing inventory to the cost of purchasing new inventory to calculate the cost of direct materials.

Table of Contents

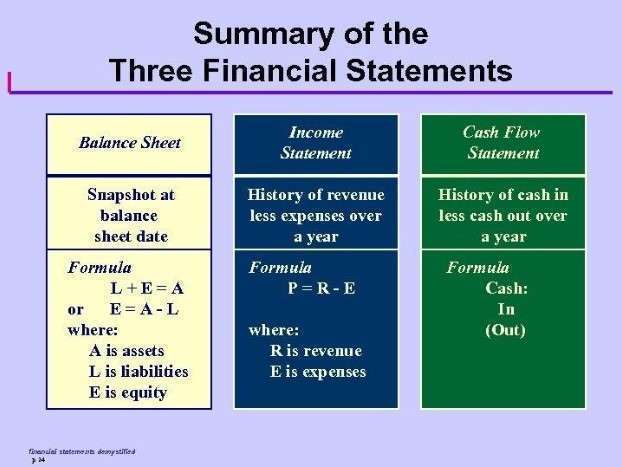

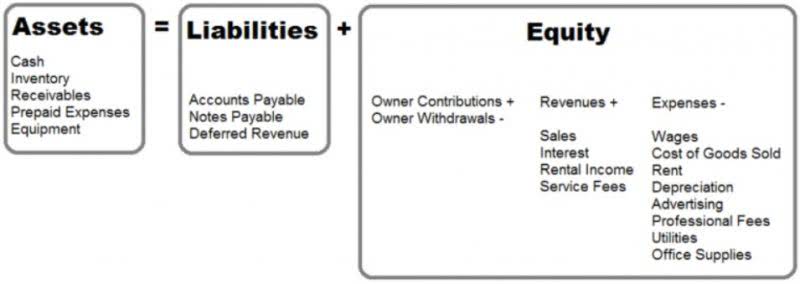

This article looks at meaning of and differences between two main cost categories for a manufacturing entity – manufacturing cost and balance sheet non-manufacturing cost. In the Canadian context, companies must adhere to the International Financial Reporting Standards (IFRS) as adopted in Canada, which provide guidelines for cost classification and financial reporting. Understanding these standards is essential for compliance and accurate financial reporting. Things that are resources owned by a company and which have future economic value that can be measured and can be expressed in dollars. Examples include cash, investments, accounts receivable, inventory, supplies, land, buildings, equipment, and vehicles.

Cost types included

Here’s a hypothetical example to show how this works using the price of oil. If production costs varied between $20 and $50 per nonmanufacturing costs include barrel, then a cash-negative situation would occur for producers with steep production costs. These companies could choose to stop production until sales prices returned to profitable levels.

- Other manufacturing overhead items are factory building rent, maintenance and depreciation for production equipment, factory utilities, and quality control testing.

- Figure 2.4 shows examples of production activities at Custom Furniture Company for each of the three categories (we continue using this company as an example in Chapter 2).

- Like direct materials, it comprises of a significant portion of total manufacturing cost.

- These minor types of materials, often called supplies or indirect materials, are included in manufacturing overhead, which we define later.

- To arrive at the cost of production per unit, production costs are divided by the number of units manufactured in the period covered by those costs.

- Cost of Goods Sold is a general ledger account under the perpetual inventory system.

These costs are reported on a company’s income statement below the cost of goods sold, and are usually charged to expense as incurred. Since nonmanufacturing overhead costs are treated as period costs, they are not allocated to goods produced, as would be the case with factory overhead costs. Since they are not allocated to goods produced, these costs never appear in the cost of inventory on a firm’s balance sheet. Manufacturing costs other than direct materials and direct labor are categorized as manufacturing overhead cost (also known as factory overhead costs).

Leave A Comment